Cornell Pumps, Parts, and Services

Since 1946, the Cornell Pump Company has delivered unmatched performance with high-efficiency pumps for the municipal, agricultural, mining, refrigeration, and food processing markets. As Western Canada’s largest Cornell Pump Company dealer, we supply genuine Cornell pump parts and dependable service for even the most demanding environments.

Clear Liquid Pumps

Cornell Pump Company produces world-renowned clear liquid pumps recognized for their durability, reliability, and efficiency in the most demanding conditions imaginable. These pumps serve various industrial, agricultural, and municipal applications. With multiple configurations available, including horizontal, vertical, close-coupled, and SAE engine-mounted, Cornell offers solutions for diverse pumping needs.

Engineered for unmatched performance, Cornell pump models can save you thousands of dollars annually through high energy efficiency and reduced energy costs. The broad selection of clear liquid pumps consistently meets and exceeds optimum efficiency standards.

When considering a clear liquid pump, trust Chamco and our available supply of Cornell pumps to deliver innovative solutions built to handle demanding environments.

Cutter Pumps

Cornell Pump Company’s cutter models address the need across industries to reduce clogging from ragging. The blade cutter design allows for minimal efficiency loss while handling aggressive plugging. Once a Cornell cutter pump is installed, operations see a dramatic increase in up-time and significant yearly savings. With Chamo’s distribution network for Cornell pumps, cutters can be added to more than 30 different pump models.

Built for durability, efficiency, and innovation, Cornell cutter pumps are hardened to extend lifespan and shaped to minimize flow restrictions. These cutter pumps also reduce labour that would otherwise be spent clearing clogs from pump systems.

To maximize uptime and minimize costs on labour and outages, a Cornell cutter pump is the ideal solution for your applications.

Food Process Pumps

The engineers at Cornell Pump Company recognize the vital role food-handling pumps play in manufacturing processes, and so do we. Cornell food process pumps can move even the most delicate food products without damage, using an innovative single-port impeller and offset volute design.

Known worldwide for quality and reliability, Cornell Pump Company has earned its reputation by engineering centrifugal pumps that deliver continuous, trouble-free service. In fact, many models sold in the 1950s still operate with the same dependable performance today.

Food processing systems demand pumps that are both efficient and economical, and with rising energy costs, conservation and efficiency are critical. Cornell pumps maintain exceptional hydraulic efficiencies and pair with energy-efficient motors to help reduce long-term operating expenses.

Hot Oil Pumps

Cornell Pump Company’s hot oil pumps feature enhanced vapour handling and advanced sealing technology for hot oil. In fryer applications, water often travels along the bottom in a liquid phase at 392°F (200°C) before reaching the pump suction, where the impeller breaks it into droplets that flash into steam. Typically, this entrained steam would reduce head and flow, but Cornell’s innovative anti-cavitation system helps prevent entrained steam and maintains stable performance.

The metal bellows mechanical shaft seal, with an optional water-cooled seat, supports temperature requirements up to 550°F (288°C). This proven sealing method, developed through years of field testing, provides food processors with a reliable and cost-effective solution.

Metal bellows seals ensure consistent performance in extreme temperature services, while the bellows leaf construction increases metal dependability and provides more uniform compression for long-lasting durability.

Hydro Turbines

You don’t need a raging river to benefit from the energy savings a Cornell hydro turbine can provide. With heads as low as 50 feet and flows starting at 90 gallons per minute, these turbines produce usable energy. Cornell’s high turbine efficiency is comparable to specialized imported models, yet they are less complex, easier to install, and require less maintenance. Cornell turbines are available in a wide range of mounting styles and configurations, and with many new and innovative design features, resulting in high performance.

Municipalities, industrial plants, HVAC systems, and farms increasingly use hydro turbines to generate power as a revenue stream or to offset energy demands and costs. The key to the system is using excess head to drive a turbine. This technology makes hydro turbines a practical option for building managers, farmers, resorts, industrial facilities, and municipalities wanting to reduce energy demand. In many cases, water-driven turbines from a natural or process stream can produce enough electricity to pay for themselves quickly.

Immersible Pumps

Cornell Pump Company delivers unique, industry-leading immersible pump solutions for various industries. Our approach to immersible pumps is to take a TEFC motor that is designed to run in air 100% of the time and adapt it to run submerged 1% of the time (in case of a flood).

The core design of an immersible pump incorporates a premium inverter-duty, P-Base or C-Face blower-cooled TEBC motor. This fully enclosed motor is cooled by a blower mounted on top. If submerged, the blower shuts down without affecting operation, while the surrounding media cools the motor, similar to an actual submersible design.

To protect against water infiltration, Cornell Pump Company’s immersible models feature a triple-redundant sealing system featuring a patented hydro seal. The motor-end bell housing applies the ‘inverted cup’ principle to trap an air bubble under the motor as water rises, keeping it away from the shaft seal. Combined with the hydro seal, this system expels water and reduces the risk of leaks along the shaft.

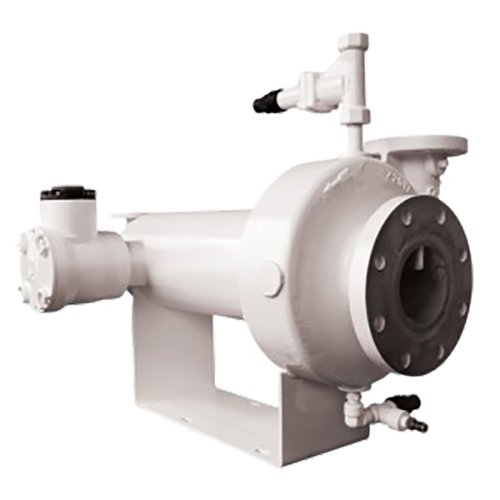

Refrigeration Pumps

Cornell Pump Company’s refrigeration models have been successfully applied in food processing, refrigeration, cold storage, ice production, and turbine inlet cooling. These pumps are widely used in liquid overfeed and transfer applications with anhydrous ammonia, aqueous ammonia, and halocarbons such as R-22 and other approved refrigerants.

Recent innovations in Cornell Pump Company refrigeration systems focus on enhanced vapour handling and improved NPSHR characteristics. These advancements have been integrated into liquid overfeed designs while maintaining four-pole or six-pole operating speed for close-coupled units.

Self-Priming Pumps

Cornell Pump Company’s self-priming models are engineered for durability, efficiency, and lasting service. The STX, STL, and STH self-priming pump lines carry on Cornell Pump Company’s legacy of innovative equipment trusted across industrial, municipal, and agricultural markets.

The self-priming pump line surpasses competitor efficiency ratings without compromising lift capability, which means energy cost savings throughout the pump’s lifespan.

Additionally, the Cycloseal® sealing system is one of Cornell’s most recognized pump head innovations. This sealing system extends seal life and ensures reliable operation under the most demanding conditions.

For operators with existing self-primers, the Cornell Pump Company retrofit program allows STX rotating assemblies to integrate seamlessly into your existing pump volute.

Solids Handling Pumps

Since the 1940s, Cornell Pump Company has produced a wide range of solids-handling pump models and mounting configurations, with discharge sizes from 3” to 30”, to handle the most challenging solids applications.

Cornell solids handling pumps tackle the toughest materials with options such as chopper impellers and cutter assemblies. Many models are also available in CD4MCu for added resistance to corrosion and pitting from abrasive solids.

Built with a robust design, thicker shafts, heavier casting walls, and fully machined impellers, Cornell pumps offer long-lasting durability, efficiency, and service, making them the premier choice for solids applications.

Slurry Pumps

Cornell Pump Company’s slurry models expand their line of dewatering solutions into abrasive mining applications. Featuring the patented Cycloseal® sealing system, these pumps are designed to operate reliably without the need for flush water.

The Cycloseal® design, with unique deflector vanes, works with the expeller to create a cyclo-action that removes abrasive material and solids from the seal area while purging air and gas pockets. This process extends seal life and eliminates the need for water flush or venting.

All Cornell Pump Company slurry models equipped with Cycloseal® technology can include the RunDry™ feature, which lubricates seal faces even when no liquid is in the casing. This option is essential when the pump must run dry for extended periods or suddenly lose prime.

Unlike traditional systems, this Cycloseal® design requires no external flush water, grease cups, filters, piping, or instrumentation typically needed with packing or double mechanical seals.

Submersible Pumps

Cornell’s hydraulic submersible models are built exclusively with Permco motors.

These industry-leading submersible pumps offer features unmatched by other producers, including:

- Flows up to 150 GPM

- Speeds up to 2400 RPM

- Working pressure up to 4000 PSI

- Heavy-duty sleeve bushing design in a medium/small frame

- Doweled and high-strength cast iron construction

- High-strength alloy steel gear and shaft sets

- Pressure-balanced wear plates maintain high pump efficiency throughout all operating ranges

- 100% factory tested

NSF/ANSI 61 Certified Pumps

NSF/ANSI 61 Certification enables Cornell pump distributors to specify pumps for installations where compliance is required, demonstrating a commitment to safe and quality manufacturing standards.

Designed for portable water applications in municipalities and housing developments, these Cornell pumps can be used to transfer water from wells, rivers, and reservoirs to treatment facilities, intra-facility, and end-users. Useful in retrofits to abate lead and other contaminant issues, these pumps are also applicable in agricultural irrigation, where lead content is regulated.

The Water Quality Association (WQA), an Illinois-based testing organization, awarded 23 Cornell pump models the Gold Standard NSF/ANSI 61 certification. Working with WQA, Cornell Pump Company submits product samples at prescribed intervals to maintain this trusted certification.

Cornell Pump Parts

Chamco is proud to be the exclusive Cornell Pump Company dealer in Western Canada. We offer a complete range of OEM replacement components to help you minimize downtime and keep your system operating at peak performance. Genuine Cornell pump parts are manufactured to exact standards, protecting your warranty and ensuring long-term durability.

Cornell Pump Company also supplies customized repair kits for select models for added convenience. These kits include essential components for routine maintenance, such as:

- Shaft sleeve

- Wear ring

- Impeller washer

- Lockscrew kit

- Vol. gasket

- Mechanical Seal

- Impeller key

- Impeller shims

- V-ring

- Lipseals

Contact a Chamco representative today for details on specific Cornell pump parts, repair kits, and pricing.

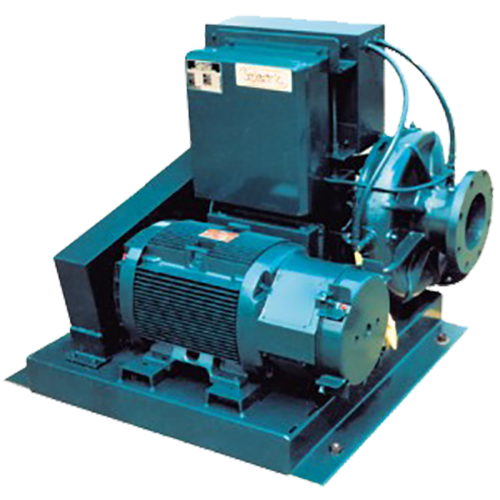

Cornell Pump Engineered Systems

Chamco takes pride in being the exclusive provider of engineered systems built with Cornell Pump Company solutions across Western Canada. Integrating the most reliable and efficient pumps is essential for designing systems that exceed customer expectations.

Incorporating Cornell Pump Company models into our engineered systems delivers unmatched performance in every application. Leveraging the proven reliability of Cornell pumps, Chamco ensures every engineered system is backed by quality and long-term service. For systems that combine innovation with a robust design to handle the most demanding environments, turn to Chamco and Cornell Pump Company, the premier choice in Western Canada.

From 6 locations across Western Canada, we service the following areas:

British Columbia

Burnaby

Creston

Delta

Drayton Valley

Fort St. James

Fort St. John

Kamloops

Kootenays

Langley

New Westminster

Okanagan

Prince George

Prince Rupert

Richmond

Sparwood

Sunshine Coast

Surrey

Vancouver

Vancouver Island

Alberta

Athabasca

Calgary

Camrose

Canmore

Cold Lake

Drumheller

Edmonton

Evansburg

Fort McMurray

Fort Saskatchewan

Grande Prairie

High Level

Hinton

Leduc

Lethbridge

Lloydminster

Medicine Hat

Nisku

Peace River

Red Deer

Rocky Mountain House

Slave Lake

St. Paul

Stettler

Turner Valley

Wainwright

Whitecourt

Wood Buffalo