CASE STUDY

How Chamco Developed an Innovative Dual-Purpose Fire and Process Pump Package for a BC Mine

Project Background

In 2023, a new gold mine in BC needed a fire pump and process water pump package for its process plant that was under construction.

The customer needed a partner who could work with them to solve their unique pumping challenges with one comprehensive package under a tight timeline.

The Challenge

Chamco was presented with a complex puzzle of engineering, logistical, and scheduling challenges to provide a comprehensive fire and process pump package for the new mine’s main process plant.

The project presented a unique challenge, as the mine wanted to integrate fire suppression and process water functionalities into a single, compact system with the washdown pumps housed in the same building as the fire pump package.

Chamco was able to innovate and think creatively to deliver a solution that met all of the mine’s needs.

Why the Gold Mine Chose Chamco

Chamco was selected for our proven expertise and strong relationships we had already built from past projects with key engineering personnel now working with the mine. Our ability to listen and respond effectively to our customer’s needs, rather than prescribing solutions, was a critical factor. Our local presence and ability to handle all aspects of the project also helped make Chamco the mine’s preferred partner for this project.

The Solution

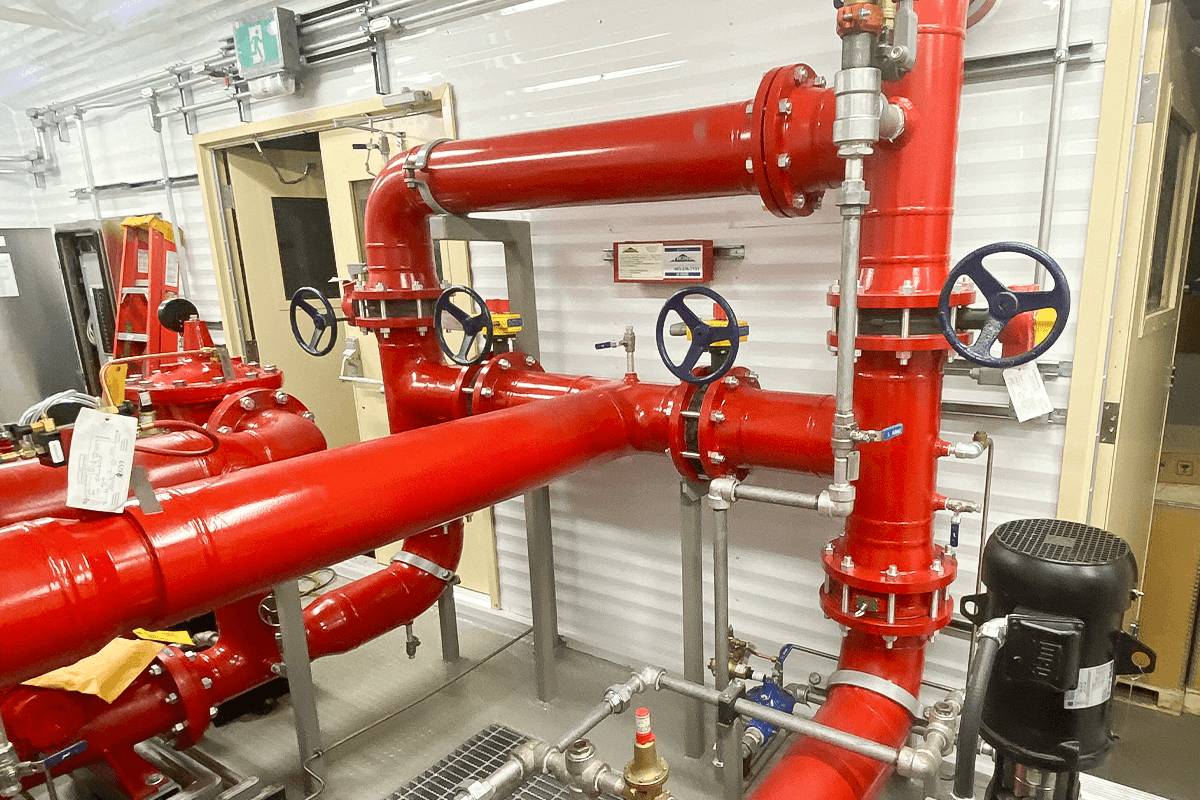

Chamco engineered a versatile pump system that integrated wash-down and firewater capabilities into one compact package, streamlining installation and optimizing space.

The Results

While the mine has not yet begun operations, the successful installation and readiness of the pump system are a significant milestone toward operational efficiency and safety compliance in the mine.

Chamco’s ability to listen, innovate, and deliver a tailored solution reinforced our position as a trusted partner, leading the mine to award Chamco with a second fire pump package project.

“Working with Chamco was easy and a smooth transition. They don’t shy away from a problem. They listened, and they reacted based on what we needed versus telling us what we should have.”

Other Case Studies

How Chamco Helped A Decommissioned Mine Meet and Maintain its Environmental Obligations

chamco2023-03-31T19:08:48-06:00In 2019, a decommissioned mine in British Columbia needed to update its existing barge to meet strict environmental requirements. The barge had reached the end of its lifespan and was also getting damaged from being dragged in and out of the pond.

How Chamco Provided a Custom Fuel Pump System for a Diamond Mine Under Extreme Conditions

chamco2023-01-10T10:15:31-07:00In 2017, a diamond mine in the Northwest Territories needed to build large fuel storage and distribution facilities and approached Chamco to help with a fuel pump system.

How Chamco Helped a Gold Mine Move Water in Challenging Conditions

chamco2023-01-10T10:16:04-07:00In 2019, a gold mine in BC built a new paste plant and needed a system to easily move water from an existing pond over a large distance and up a hill to the new plant. Due to the unique requirements of this installation, they couldn't use any of their existing systems in this challenging environment and turned to Chamco to help them design a new system.