CASE STUDY

How Chamco Helped a Gold Mine Move Water in Challenging Conditions

Project Background

In 2019, a gold mine in BC built a new paste plant and needed a system to easily move water from an existing pond over a large distance and up a hill to the new plant. Due to the unique requirements of this installation, they couldn’t use any of their existing systems in this challenging environment and turned to Chamco to help them design a new system.

The Challenge

The customer needed to move water from a pond to their new plant but the climate and landscape both presented some challenges. The system needed to withstand the harsh winter conditions and be able to move the water a long distance and up a steep gradient.

Why the Gold Mine Chose Chamco

Prior to this project, Chamco had already established a strong relationship with this customer. The customer was pleased that Chamco could be a one-stop-shop for this project, providing the pump solutions and deicing systems, and assisting with the electrical challenges. With many successful projects completed for the customer over the years, including a barge, vertical turbine pumps and compressor systems, it was natural that they turned to Chamco as a partner they could trust to meet the many challenges of this project.

The Solution

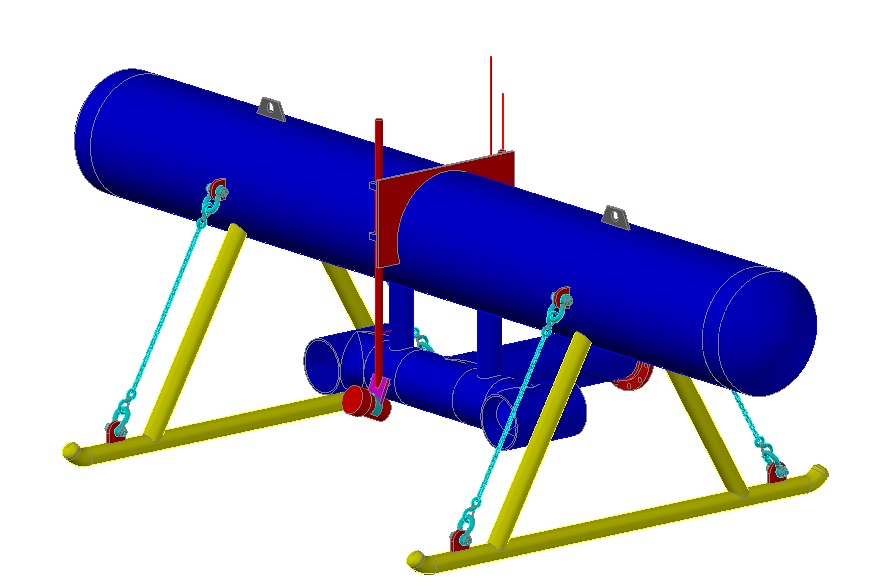

Chamco overcame the many challenges to provide a system that included one self-priming water package, one booster package and a decanter, which allowed the mine to easily move water from the pond to the plant. Shore-based pump systems including self-priming Cornell pumps proved to be the best option for this project. When the system starts, there doesn’t need to be water in the pipeline because the self-primer on the front of the pump will slowly vacuum up water until the pump is completely flooded. And once water starts to flow in a self-priming pump, it will continue to flow until it’s shut down.

The Results

Chamco solved numerous challenges to deliver a system that ensured the mine could easily move water effectively, despite the harsh winter conditions, elevation, and distance issues. With open channels of communication and a relationship built over many years, the customer never lost faith in Chamco’s ability to deliver what they needed. Now that the system is installed, it continues to operate with very little human intervention.

“Our customer knew that we were problem solvers. They needed to move water to a very remote location and there were a number of issues, including the power, keeping the system from freezing, moving water, and not sucking in sludge. They had an issue and we offered a solution.”

Learn more about how Chamco can help with your project.

Other Case Studies

How Chamco Helped A Decommissioned Mine Meet and Maintain its Environmental Obligations

chamco2023-03-31T19:08:48-06:00In 2019, a decommissioned mine in British Columbia needed to update its existing barge to meet strict environmental requirements. The barge had reached the end of its lifespan and was also getting damaged from being dragged in and out of the pond.

How Chamco Provided a Custom Fuel Pump System for a Diamond Mine Under Extreme Conditions

chamco2023-01-10T10:15:31-07:00In 2017, a diamond mine in the Northwest Territories needed to build large fuel storage and distribution facilities and approached Chamco to help with a fuel pump system.

How Chamco Helped a Gold Mine Move Water in Challenging Conditions

chamco2023-01-10T10:16:04-07:00In 2019, a gold mine in BC built a new paste plant and needed a system to easily move water from an existing pond over a large distance and up a hill to the new plant. Due to the unique requirements of this installation, they couldn't use any of their existing systems in this challenging environment and turned to Chamco to help them design a new system.