CASE STUDY

How Chamco Provided a Custom Fuel Pump System for a Diamond Mine Under Extreme Conditions

Project Background

In 2017, a diamond mine in the Northwest Territories needed to build large fuel storage and distribution facilities and approached Chamco to help with a fuel pump system.

The Challenge

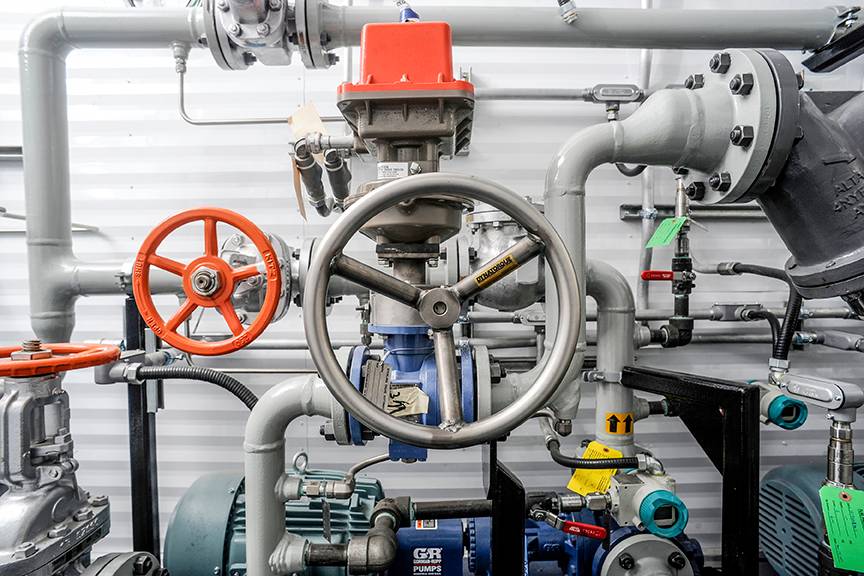

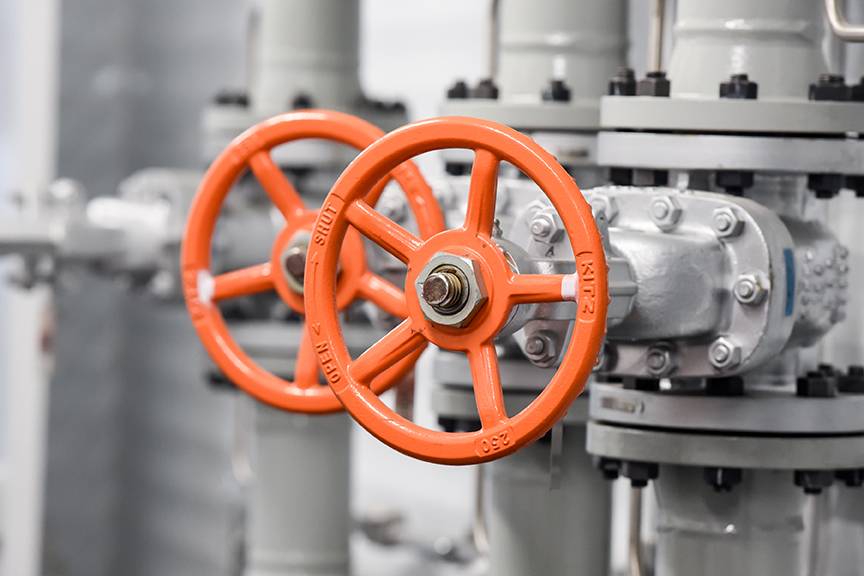

The customer needed a fuel distribution system to offload fuel from their tanker trucks and move it to their fuel storage tanks. They turned to Chamco to design a full fuel pump system that would work with their tanks and could pump gasoline, diesel, and jet fuel.

Why the Mine Chose Chamco to Supply Their Fuel Pump System

Chamco has decades of experience in building custom, complex fuel pump modules according to our customer’s needs. The mining company had an existing relationship with Chamco and we had previously provided a number of systems to the mine, including fire packages, air packages, and smaller fuel transfer packages.

When the mine needed a full turn-key package that could solve all their fuel needs onsite, the customer knew Chamco would be able to overcome their challenges and deliver the packages they needed.

The Solution

Chamco overcame numerous challenges to provide a complete fuel pump solution to the mine that ensured they could offload and distribute their fuel easily and safely.

The Results

Chamco provided a turn-key system that met all the unique challenges and requirements for this project, providing a full solution to the mine’s on-site fuel needs. We guided our customer throughout the entire process and ensured they received an efficient, cost-effective package. The fuel pump system was also designed in a way that it could easily be expanded in the future.

Chamco worked very closely with the customer to ensure all their requirements were met. Everything was done on time and on budget and the customer was very happy with the results.

“This was a fun project from the proposal phase to seeing it all come together at the end. We were able to provide a full turn-key package that met all our customer’s onsite fuel needs on time and on budget.”

Learn more about how Chamco can help with your project.

Other Case Studies

How Chamco Helped a Major Oil and Gas Company Standardize Air Packages Across Multiple Locations

chamco2024-07-31T14:25:58-06:00In 2013, one of Canada’s largest crude oil and natural gas producers faced challenges with consistency in its air compressor systems across its oil pad fields. The company needed to develop a standardized air compressor package to streamline operations, reduce engineering time, and reduce spare parts inventory across multiple locations.

How Chamco Developed an Innovative Dual-Purpose Fire and Process Pump Package for a BC Mine

chamco2024-04-17T11:40:20-06:00In 2023, a new gold mine in BC needed a fire pump and process water pump package for its process plant that was being constructed. The project presented a unique challenge as the mine wanted to integrate fire suppression and process water functionalities into a single compact system with the wash-down pumps housed in the same building as the fire pump package.

How Chamco Helped A Decommissioned Mine Meet and Maintain its Environmental Obligations

chamco2023-03-31T19:08:48-06:00In 2019, a decommissioned mine in British Columbia needed to update its existing barge to meet strict environmental requirements. The barge had reached the end of its lifespan and was also getting damaged from being dragged in and out of the pond.