Imagine the peace of mind knowing your fire protection system is dependable.

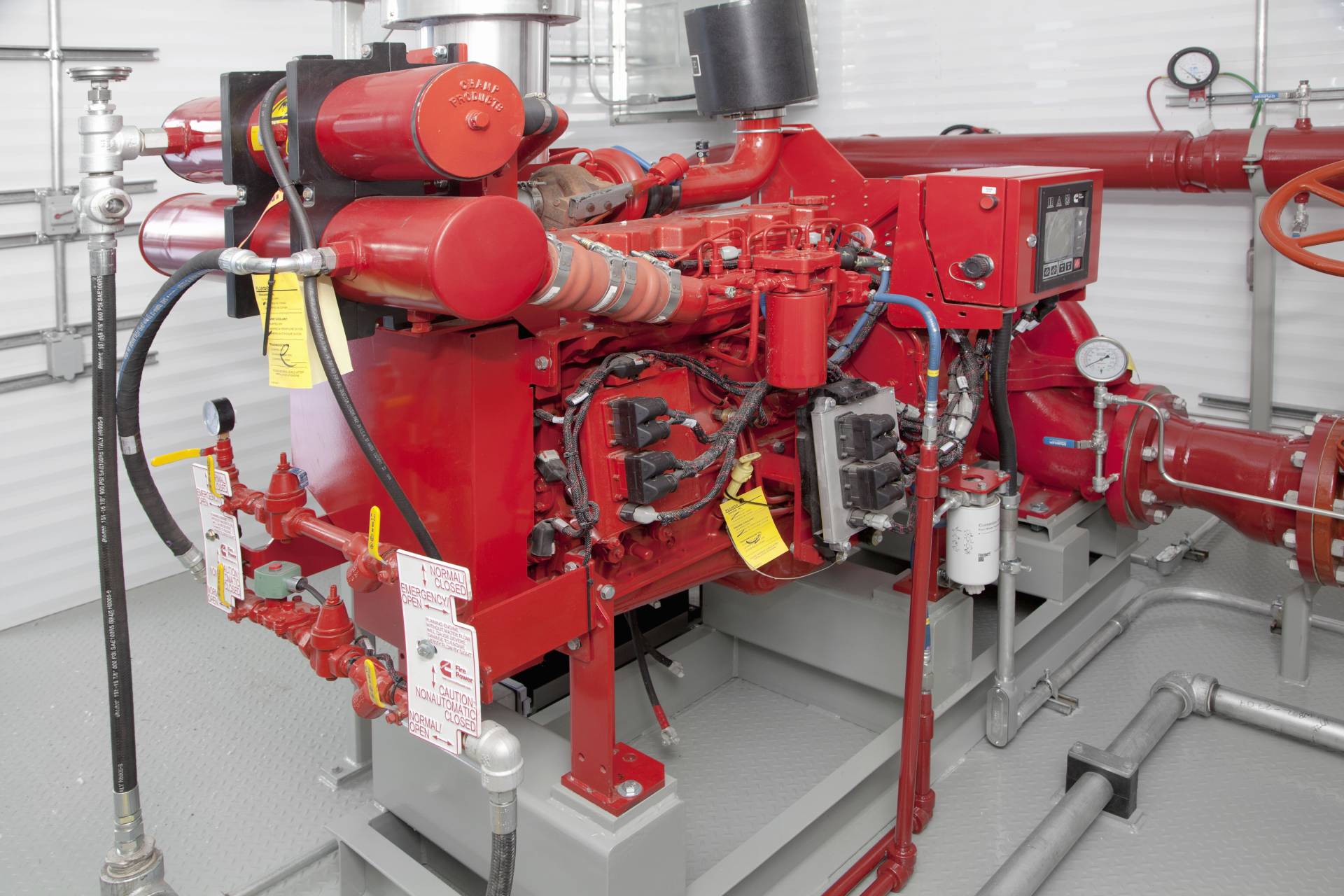

One of the keys to this confidence is a meticulously installed fire pump.

When it comes to fire pump installation, you must ensure every aspect of your fire pump system, from the water supply to electrical infrastructure and space, is meticulously planned and executed, so your fire pump is ready to perform when needed.

In this article, we’ll explain the key fire pump installation requirements and other factors to consider before installing fire protection pumps.

Factors to Consider Before Installing a Fire Pump

Water Supply

When installing fire pumps, it’s important to consider the water supply’s cleanliness, total volume, and replenishment rate.

Clean water ensures the fire pump operates efficiently without clogging, while sufficient volume, water pressure, and replenishment rates ensure the system can effectively sustain firefighting efforts.

If you don’t have sufficient water pressure or volume, you may need to install a booster pump or upgrade the water line.

Additionally, if you don’t have an adequate water supply, consider installing a water storage tank to provide a dedicated and reliable water source for your fire pump.

Electrical Considerations

Proper electrical infrastructure ensures your fire pump operates safely and reliably. That’s why paying attention to these electrical considerations is key to keeping your fire pump system operational:

- Ensure you have a dedicated, reliable power supply, including a backup like an emergency generator

- Verify that your electrical service can handle the pump’s load, both at startup and during regular operation

- Use appropriate wiring and conduits for the installation environment

- Set up dedicated control panels with manual/automatic controls, alarms, and monitoring systems that comply with National Fire Protection Association (NFPA) 20 standards

- Add motor protection devices like circuit breakers and overload relays

- Keep voltage drop to a minimum to ensure the pump gets enough power

- Properly ground and bond all electrical components

- Follow all local, national, and international electrical codes

Space Constraints

When installing a fire pump, it’s important to think about space.

The fire pump room should be spacious enough to accommodate the pump, motor, control panels, and any auxiliary fire pump equipment, while allowing for adequate ventilation to prevent overheating.

There should also be sufficient clearance around the equipment to facilitate regular inspections, maintenance, and repairs. Additionally, the layout of fire pump rooms must provide easy access to the pump and its components, complying with local fire codes and NFPA 20 regulations.

Site-Specific Requirements

Don’t overlook the unique site-specific requirements that can go beyond basic NFPA rules.

For example, some sites may restrict the use of certain materials, such as requiring specific shafting or impeller metal compositions due to trace elements in the water supply. There may even be noise pollution concerns requiring oversized exhaust silencers.

It’s important to understand these site rules and integrate them with fire codes to ensure your fire pump system is compliant and acceptable.

Determining the Right Fire Pump Type and Size for Your Facility

The right type of fire pump for your facility depends on the risk level on-site and the amount of protection required. This assessment is typically conducted by engineering teams, the fire marshal/fire department, or your insurance company. They evaluate the specific risks and outline the protection needed based on your specific site requirements and in accordance with NFPA and other local and international regulations.

Fire Pump Installation Regulations & Requirements

When installing fire pumps, it’s essential to follow specific standards and regulations to ensure safety and compliance. Here’s a breakdown of what you need to consider:

NFPA (National Fire Protection Association)

NFPA 20 serves as the main guide for fire pump installation and initial performance testing. It’s crucial to check and re-check that all system requirements are met.

Additionally, being familiar with NFPA 25, which covers annual testing and maintenance, helps avoid installation errors that might pass the initial test but cause issues later.

International Standards

In addition to national standards, it’s important to be aware of international regulations, especially if your facility works with international partners.

The International Code Council (ICC) provides guidelines that often align with or supplement NFPA standards, ensuring broader compliance and safety.

Local Authority Having Jurisdiction

Your local Authority Having Jurisdiction (AHJ) is key in approving and overseeing fire pump installations. Local codes and regulations can vary widely, so it’s important to know the specific requirements of your area. These regulations might include additional safety measures, specific materials, or unique installation techniques.

Manufacturer Installation Instructions

Before commissioning a fire pump, it’s essential to follow the manufacturer’s installation instructions and requirements meticulously.

Each component—whether it’s the pump unit itself, the engine, or the fire pump controller—comes with specific guidelines.

The installation and operation manuals from the pump manufacturer provide step-by-step instructions on how to properly set up the pump. Similarly, the equipment startup checklist from the engine manufacturer details what needs to be done for the engine.

Ensuring that all these instructions are aligned will ensure a successful and compliant installation and guarantee that the pump will operate safely and efficiently right from the start.

How Chamco Can Help With Your Fire Pump Installation

When it comes to installing fire pumps, using an OEM-trained technician is a must.

At Chamco, our highly trained technicians have supported our customers with their fire pump solutions and services for over six decades.

Our technicians have an in-depth understanding of fire pump equipment and are familiar with the latest updates, regulations, and best practices for installation.

We develop fire pump systems using end suction, vertical inline, vertical turbine, and horizontal split case pumps, all built to applicable local, international, and NFPA standards to ensure the long-term reliability and performance of your fire pump system.

Contact us today to discuss your fire pump installation needs.