When protecting your industrial facility, there’s just no room for compromise.

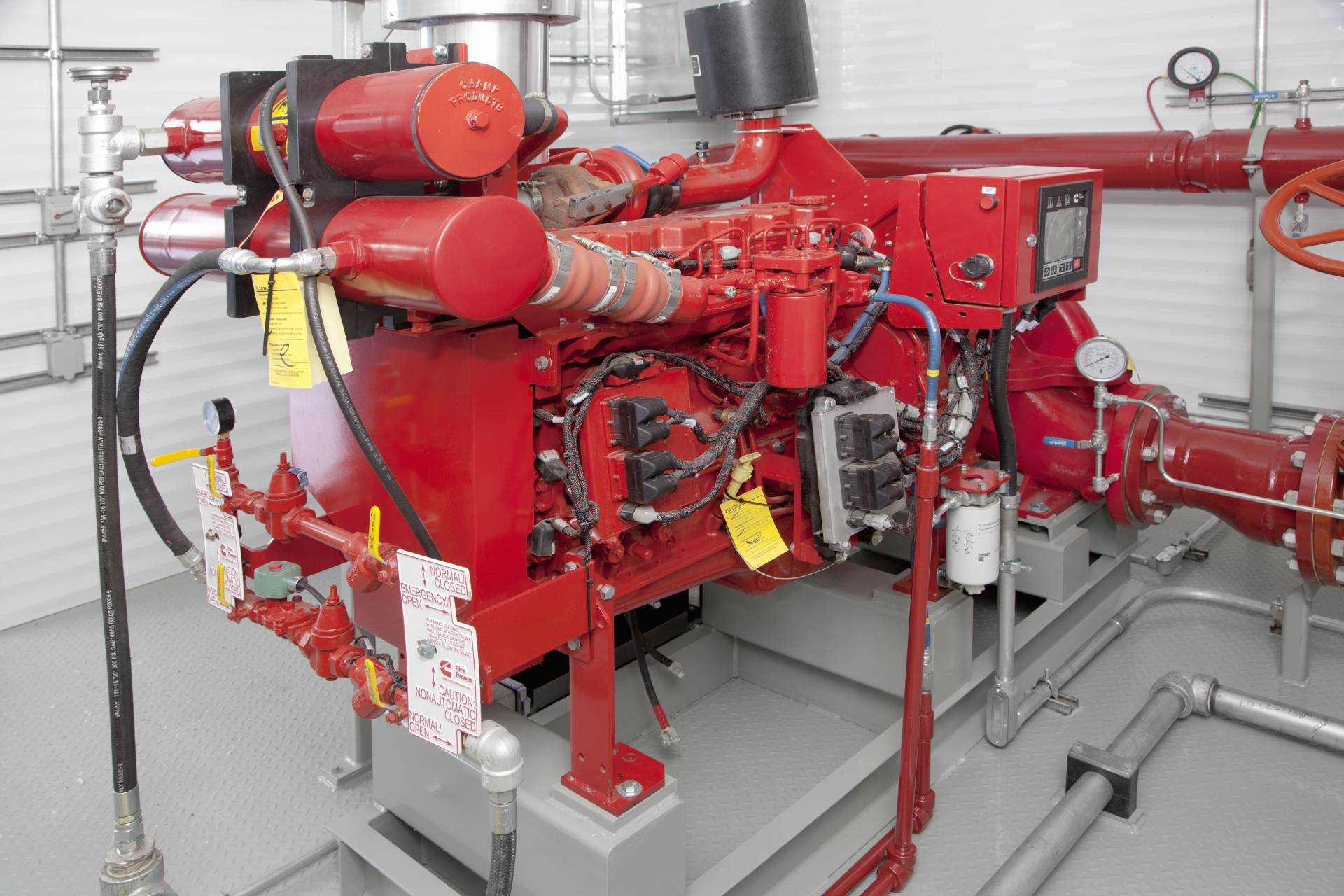

Your fire pumps play an important role in the fire protection system of your industrial facilities, and as a property owner, you have a responsibility to ensure your fire pumps are always operational to protect your people, buildings, and assets in the event of a fire.

Fire pump systems can fail due to a variety of reasons, including mechanical issues, corrosion, age, or lack of maintenance, so it’s essential to keep them in proper working order. Regular testing and inspection are not only a requirement but can help identify and address issues before they become critical and ensure that your system is in good working order when needed most.

If you have a diesel or electric fire pump in your building or facility, it is important that someone is assigned to oversee the periodic inspection, maintenance, and testing required for this equipment. You also need to have the relevant training and work with appropriately trained contractors capable of working on this type of equipment.

The National Fire Protection Association (NFPA) has established standards for routine inspection, testing, and maintenance requirements for fire pumps and it’s important that businesses follow these guidelines to keep their fire pump systems operational.

Local fire departments or marshals and your insurance provider can also help you to understand the responsibilities of having this type of equipment. A local Authority Having Jurisdiction (AHJ), that is either your insurer or fire marshal, also dictates the requirements for a fire pump system set-up as well as inspections and maintenance.

Below is a brief overview of NFPA-25 fire pump testing requirements, and some of the steps needed to keep your fire pump working optimally and always ready to keep your facility safe from fires.

For a full list of the requirements, we recommend familiarizing yourself with the NFPA-25 standard for inspection, testing and maintenance of water-based fire protection systems. You can also reach out to your local fire department or marshal as well as your insurance provider or a preferred and reputable contractor for support.

The Requirements for Fire Pump Testing

Fire pump equipment can sit on standby for long periods of time as it is only needed in the event of a fire. Fire pump equipment must be flow tested periodically to ensure it meets the original factory performance. The frequency of testing is dictated by NFPA as well as your system set-up and local jurisdiction requirements.

The NFPA recommends weekly and annual inspections and tests that should be performed to check that your equipment is fully operational.

When conducting inspections and testing of your equipment, always ensure you are adequately trained to be completing the work and conducting them in accordance with the manufacturer’s recommendations.

Weekly Fire Pump Tests

If you have a diesel- or engine-driven fire pump, NFPA-25 requires you to complete a weekly inspection and no-flow test and this should be completed in accordance with NFPA-25 as well as the OEM equipment provider’s guidelines.

Minimum weekly inspections typically should include checking your diesel and electric pumps by doing the following:

Check the Pump House and Room

- Ensure the temperature is adequate and above 4℃.

- Check that the ventilating louvres are free to operate.

- Ensure excessive water does not collect on the floor.

- Check that the pump coupling guard is in place.

Check the Pump System

- Ensure the pump suction and discharge valves are fully open, and the piping is leak-free.

- Check the suction pressure gauge to ensure it reads within an acceptable level.

- If water is supplied by a reservoir, check the reservoir has the required water level.

- Ensure any wet pit suction screens are unobstructed and in place.

- Check that the water flow test valves are closed.

- Check that the hose connection is closed.

- Check that the line to test valves is water-free.

Check the Electrical System Conditions

- Ensure the controller pilot light and the transfer switch normal pilot light are on.

- Check that the isolating switch is closed for standby (emergency source).

- Check that the reverse phase alarm pilot light is off.

- Check that the oil level in the vertical electric motor is within an acceptable range.

- Check that the power to the jockey pump is provided and the jockey pump maintains adequate pressure to the system.

Check the Diesel Systems Conditions

- Ensure that the fuel tank is at least two-thirds full

- Check that the controller selector is in the auto position.

- Ensure all battery voltage readings are within an acceptable range and battery charging current readings are within an acceptable range.

- Check that the battery pilot lights or failure lights are off.

- Ensure the engine running time metre is reading.

- Check that the oil level is in the right angle gear drive within an acceptable range.

- Check that the crankcase oil level is within acceptable range.

- Ensure the cooling water level is within acceptable range.

- Ensure the electrolyte level in the batteries is within an acceptable range, and terminals are corrosion-free.

- Check that the water jacket heater is operating.

Fire pump no-flow testing is also required on a weekly basis depending on your type of equipment and requirements from your Authority Having Jurisdiction.

Annual Fire Pump Tests

Annual fire pump tests are more involved and should be performed by a competent and certified professional who will be able to provide a full report on the operation of your fire pump system.

Annual fire pump tests include a flow test to measure the performance of your pump and driver to verify it is meeting the original design requirements.

The annual flow test measures the flow and pressure of your fire pump and can uncover any issues with your pump’s flow and water supply.

The test involves running the pump at various flow outputs and up to 150% of the pumping capacity.

An annual test typically takes about a day, although this can take longer depending on the complexity of your fire pump system.

The Implications of Fire Pump Testing Failure

If your fire pump fails a test, you may need a further inspection to determine what pump components are causing the issues.

Depending on your findings, you’ll likely need to develop a plan for corrective maintenance, including pulling the pump and sending it to a shop for assessment, or, depending on the age of the pump, consider replacing the entire pump.

Either way, you have a responsibility to ensure your pump is either restored to full-function pumping capacity or replaced with a new pump to ensure you remain compliant with NFPA recommendations.

How Chamco Can Help With Your Fire Pump Testing

At Chamco, we are committed to staying on top of the latest developments in fire pump solutions, and we have the expertise to support our customers in all their fire pump system testing and inspection requirements.

Chamco has experts on staff specializing in NFPA-25 inspection, testing, and maintenance of water-based fire protection systems. Our highly experienced, factory-trained technicians can assist you with all your fire pump inspection needs.

Our teams have the knowledge and experience to ensure your fire pumps and their components are functioning optimally, and your facility is always protected.

When you work with a fire pump specialist like Chamco for your fire pump inspections and testing, you’ll receive a report documenting the full test results, including pressure readings, pump suction readings, details about the pump’s flow, and any issues that could affect the functioning of your fire pump system.

Our technicians will work with you to provide an action plan to help you decide whether you need to repair or replace the pump and can assist with a full fire pump maintenance plan.

Contact us today to get started with your annual fire pump inspections and learn more about our preventative pump maintenance programs to ensure your fire pump system is in tip-top shape and ready to protect your facility when needed.