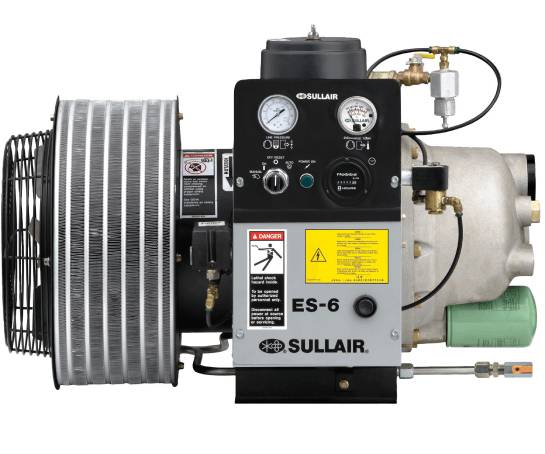

Are you searching for an air compressor robust enough to handle the relentless demands of continuous, heavy-duty operation in extreme conditions? Look no further than the Sullair ES-6, a game-changer in industrial air compression technology.

Traditional compressors, often designed for less demanding environments, fall short in terms of durability and maintenance simplicity, leading to increased downtime and operational costs.

The Sullair ES-6 is the ideal solution for those operating in the most demanding environments, boasting a simple design prioritizing ease of use, minimal maintenance, and robust performance. The ES-6 is engineered for environments where downtime isn’t an option, making it a premium choice for those needing a durable and straightforward solution.

In this blog, we delve into the unique attributes of the ES-6 to underline why it has become the go-to compressor for industries requiring reliability, simplicity, and performance.

Designed for Heavy Duty, 24/7 Operation

In heavy-duty sectors like oil and gas, mining, forestry, and manufacturing, a downed compressor could mean significant operational disruptions, leading to costly delays, reduced productivity, and potential safety hazards.

Recognizing the critical impact of compressor reliability in demanding environments, the Sullair ES-6 is engineered to provide continuous, heavy-duty operation.

Built to endure the toughest conditions, from scorching summers to freezing winters and high-vibration environments, its robust construction ensures it can withstand the rigours of around-the-clock operation without compromising on efficiency or longevity.

Unlike compressors meant for lighter, intermittent use, the ES-6 thrives in environments that demand non-stop performance. This distinction makes it particularly suitable for heavy-duty sectors where continuous operation is essential.

The ES-6 is therefore especially reliable for critical tasks such as operating shovel brakes under extreme conditions, demonstrating its unmatched durability and operational excellence in demanding settings.

Operational Simplicity and Reliability

The efficiency and reliability of your equipment can make or break your productivity. With conventional air compressors, every maintenance task can turn into a complex, time-consuming ordeal, requiring specialized knowledge and causing frequent downtimes.

However, one of the hallmark features of the ES-6 is its operational simplicity.

The ES-6 is designed to be user-friendly, requiring minimal expertise for maintenance and daily operation. Its reliance on mechanical and electrical components over complex electronics means that there are fewer points of failure, making the ES-6 a model of reliability.

Compact Design

In industrial and heavy-duty applications, efficient use of space is a critical component of operational efficiency and safety.

The ES-6 distinguishes itself with its compact yet robust design, which is particularly advantageous in applications where large equipment vies for a place and space is at a premium.

Despite its smaller size, the compact design does not sacrifice performance or capability, making it an ideal replacement for older, bulkier equipment that cannot match the ES-6’s efficiency or reliability.

Unmatched Efficiency

The ES-6’s compact design also means there are 40% fewer parts than conventional compressors, which means less risk of failing parts and the ability to maintain high energy efficiency throughout the life cycle of the equipment.

The Sullair ES-6 air compressor also features a specially designed cooler and a robust inlet filter made of fibreglass, offering up to 20% more efficiency than standard paper filters. With just annual replacements needed, it ensures the compressor’s internals are well protected, and maintenance is hassle-free.

Inlet Modulation: A Unique Advantage

A standout feature of the Sullair ES-6 is its inlet modulation capability, uncommon in compressors of its size and class.

The inlet modulation feature allows for precise control over air consumption. While not primarily designed as an energy-saving feature, inlet modulation significantly enhances the compressor’s reliability by ensuring it operates within its most efficient range, thereby extending its service life.

A key aspect of this reliability enhancement is the prevention of short cycling, a common cause of compressor failure and compromised air quality through oil carryover. By eliminating short cycling, inlet modulation prevents the air quality from tarnishing due to oil carryover.

As an example of this reliability, when operating at 50% capacity, the compressor only requires 82% of the power it would typically need, significantly extending its service life and reinforcing its reliability in critical applications. In comparison, a load/no-load compressor requires 90% of its power input even at a 50% load.

Low Maintenance, High Performance

An air compressor that demands frequent, time-consuming maintenance can lead to extended downtime, increased labour costs, and compromised productivity. Fortunately, the ES-6’s design prioritizes ease of maintenance alongside performance.

The Sullair ES-6 air compressor streamlines routine maintenance, requiring only oil checks and air filter replacements at every 2,000-hour mark.

More comprehensive servicing is only necessary after 8,000 hours of 24/7 operation production time and generally takes only 8-10 hours compared to the more time-consuming maintenance typically required for belt-driven compressors. This maintenance includes swapping out four air filters, one fluid filter, and one fluid separator, and refreshing with Sullube lubricant.

This regimen cuts labour by about 30%. With 40% fewer parts to maintain than traditional belt-driven compressors, the Sullair ES–6 also reduces downtime significantly. Moreover, this maintenance efficiency contributes to the compressor’s long-term reliability and cost-effectiveness.

A Direct Drive System

The ES-6 employs a direct drive mechanism with a single motor to handle both air compression and cooling, unlike traditional air compressors that use a drive motor for air compression and an additional motor with a fan for cooling the compressor fluid and compressed air. Most compressors up to 10HP don’t have compressed air cooling through a heat exchanger, which means they have more water and contamination going into the system.

This direct drive design choice instead of the more common belt-driven approach reduces the number of moving parts, lowering the potential for failures and maintenance requirements.

Direct drive systems are inherently more reliable and efficient, translating to a longer lifespan for the compressor and reduced operational costs. At Chamco, we’ve seen ES-6 air compressors operate upwards of 70,000 loaded hours–lasting twice as long as belt-driven compressors.

Unique to the ES-6 is also its use of a 1,800 RPM motor, a departure from the standard 3,600 RPM motors seen in many competitor products.

The reduction in speed cuts down wear on the components by at least four times, with the slower rotation rate significantly reducing wear and tear, thereby extending the compressor’s life without compromising its air output.

Simplify Maintenance and Boost Productivity with the Sullair ES-6

When comparing the Sullair ES-6 to other products on the market, it’s clear that its design and features are tailored for operations that cannot afford downtime and require a reliable, efficient, and easy-to-maintain air compressor.

The unique inlet modulation feature, combined with a robust, simple design and the efficiency of a direct drive system, positions the ES-6 as a premium choice for heavy-duty applications. Whether for mining, manufacturing, or any industry in between, the Sullair ES-6 represents a smart investment for businesses looking for uncompromising performance and reliability.

Want to learn more about how the Sullair ES-6 air compressor can enhance your operations? Contact us today to discuss your industrial air compressor needs.