Nitrogen generators are an excellent option for on-demand generation of nitrogen on-site.

Their streamlined design and enhanced functionality allow businesses to produce high-purity nitrogen right where needed, minimizing dependency on external suppliers and reducing logistical hurdles.

But do you know how a nitrogen generator works?

In this article, we’ll explain how nitrogen generation technology functions and discuss the factors you must consider when implementing a nitrogen gas generation system to produce nitrogen for your facility.

The Power of a Nitrogen Generator

A nitrogen generator is an efficient machine designed to seamlessly integrate into your existing setups.

At Chamco, we supply compact, plug-and-play nitrogen generators that utilize Pressure Swing Adsorption (PSA) technology. PSA nitrogen generators employ adsorbent materials to filter out oxygen and other impurities, effectively allowing only nitrogen to pass through.

Nitrogen generators are available in sizes to suit businesses of all scales, from small to large, ensuring that even smaller operations can enjoy the benefits of consistent, on-site nitrogen supply.

These systems are versatile and customizable solutions that meet the specific requirements of different industries including laser facilities, food packaging, breweries, electronics, and pharmaceuticals, among others.

The Requirements to Set up an On-Site Nitrogen Generation System

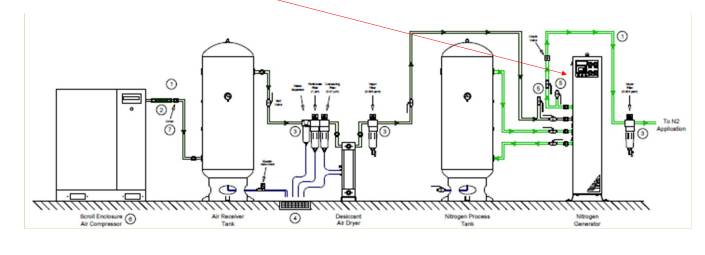

A nitrogen generation system requires a compressor and dryer for operation. If your existing compressor and dryer setup has sufficient capacity, you only need to incorporate the nitrogen generator and buffer tank to complete your setup, ensuring a streamlined process for high-purity nitrogen production.

The Nitrogen Generation Process

Source: PEAK Scientific

So let’s break it down. Here is the nitrogen generation process in a PSA nitrogen generation system.

Step 1: Air Intake

The process starts by drawing in ambient air, which is composed of approximately 78% nitrogen, 21% oxygen, and trace gases from the surroundings.

Step 2: Compression

The incoming air is compressed using an air compressor.

Step 3: Pre-Filtration

Compressed air undergoes pre-filtration before entering the PSA unit, and filters remove dust, moisture, and oil to protect the adsorbent material.

Step 4: Adsorption (Nitrogen Separation)

Compressed air is fed into the dual-pressure CMS vessels and undergoes a cycle of compression and decompression, during which oxygen is absorbed and nitrogen is passed downstream.

This not only delivers continuous nitrogen gas flow rates on a large scale, it also guards against abrasive breakdown, preventing gas supply contamination and ensuring an expected CMS lifespan of up to 20 years.

Step 5: Nitrogen Collection

The process tank ensures there are no large spikes in demand from the system. The nitrogen-enriched gas from the adsorber is collected and supplied to the application via distribution lines at various points within the facility. The generator is sized specifically to the flow rate needed, and, much like water from a faucet, nitrogen is supplied as and when needed.

The purity of the nitrogen ranges from 95% to 99.9995%will depend on the specific adsorbent material and system design.

What to Consider Before Installing an On-Site Nitrogen Gas Generator

If you’re considering implementing an on-site nitrogen generation system in your facility, there are a few things to consider:

The Purity Required

The purity level required depends on your industry. For example, a laboratory-based application may require ultra-high-purity nitrogen at 99.9995% purity, while a brewery or chemical plant that is just purging for safety to reduce flammability or reduce oxygen content might need 99.5% purity.

Current Nitrogen Flow Rate

Again, this depends on the industry and the types of machines and processes within your facility. The current flow rate can easily be calculated by looking at your consumption and dividing it by the number of hours you’re operating.

The Pressure Required

Pressure is another parameter that varies depending on the industry and application. For instance, some nitrogen generators can deliver up to 130 psi, which suits various applications—from laboratory environments and food and beverage packaging to brewery purging processes. However, high-pressure applications, such as laser cutting, demand higher pressures, around 400 psi.

The Residual Demand in the Existing Compressor

Compressed air is required to operate an on-site nitrogen generation system, so it’s important to decide whether you need to upgrade or change your existing air compressor to facilitate the addition of the nitrogen generator.

If your operation relies on a bulk tank, you might not have an air compressor if the nitrogen is fed directly into your machinery through a regulator that adjusts the pressure as needed. In such cases, integrating a nitrogen generator would necessitate acquiring an air compressor to provide the necessary compressed air for nitrogen production.

On the other hand, if your facility already has an air compressor, the key question becomes whether it has the spare capacity to support the additional demand from the nitrogen generator.

Current Nitrogen Spend

Understanding your current expenditure on nitrogen is crucial when considering an on-site nitrogen generation system, as it directly influences the decision-making process by highlighting the potential return on investment (ROI).

For instance, if you’re spending $45,000 annually on nitrogen and the complete system costs $140,000, the investment pays for itself in just under two years. Given the system’s lifespan of 15 to 20 years, the investment will offer significant long-term savings compared to a lower annual spend that may not justify the upfront cost of the generator.

How Chamco Can Help With Your Nitrogen Generation Needs

At Chamco, we supply on-site nitrogen generator systems that use high-purity nitrogen gas generators from leading manufacturers. We also offer options to lease the nitrogen generation equipment, reducing your upfront costs.

We have the experience and expertise to design the accompanying air compressor and air treatment system to ensure continuous nitrogen purity and prolong the life of your nitrogen generation system. No matter your industry or facility, we offer customizable nitrogen purity and flow rates for your unique application.

Contact us today to discuss your on-site nitrogen generation needs.