Pump failures remain one of the most common causes of unplanned downtime in industrial operations, and in nearly every case, the warning signs were visible long before the failure occurred.

Today’s facilities are under pressure to maximize uptime, reduce energy consumption, and operate with leaner maintenance teams. Traditional maintenance approaches can’t always keep pace with these demands.

This is where continuous pump monitoring is transforming reliability programs. By connecting pumps to cloud-based monitoring and control platforms, operators gain real-time visibility, earlier warnings, and greater control from anywhere. For Grundfos pumps, the Grundfos ecosystem delivers more in-depth data and functionality to support operating efficiency and setup.

Connected pumps become intelligent assets that help prevent failures and inform smarter capital planning for predictive maintenance strategies.

This article explains how cloud-connected monitoring works and how leaders can start building a more reliable, data-driven pumping strategy.

The Limits of Traditional Pump Maintenance

Most pump systems still rely on reactive or time-based maintenance approaches that fail to reflect the real-world condition of assets.

Reactive maintenance refers to issues being identified only when the system trips or the pump fails outright. By the time a technician is called in, the damage is already done.

Time-based PM schedules offer consistency but don’t align with actual performance. Some pumps are over-maintained (wasting service hours and budget), while others degrade between scheduled checks.

Data fragmentation is another constraint. Operators rely on notebooks, offline SCADA trends, or isolated OEM interfaces. No centralized, continuous view exists to help spot performance drift or detect early failure modes.

As operational demands rise and teams shrink, these models can’t deliver the reliability targets organizations need. Pump management is shifting toward continuous, real-time insight and toward tools that tie performance data directly to actionable decisions.

Why Cloud Monitoring Is Becoming Essential

Across industrial sectors, systems are operating under heavier demand, higher energy costs, and tighter staffing constraints. Aging infrastructure and rising uptime expectations leave little room for reactive maintenance.

Continuous monitoring helps fill these gaps by surfacing performance changes earlier, reducing manual reporting, and easing the workload on lean maintenance teams.

What Is Pump Cloud Monitoring?

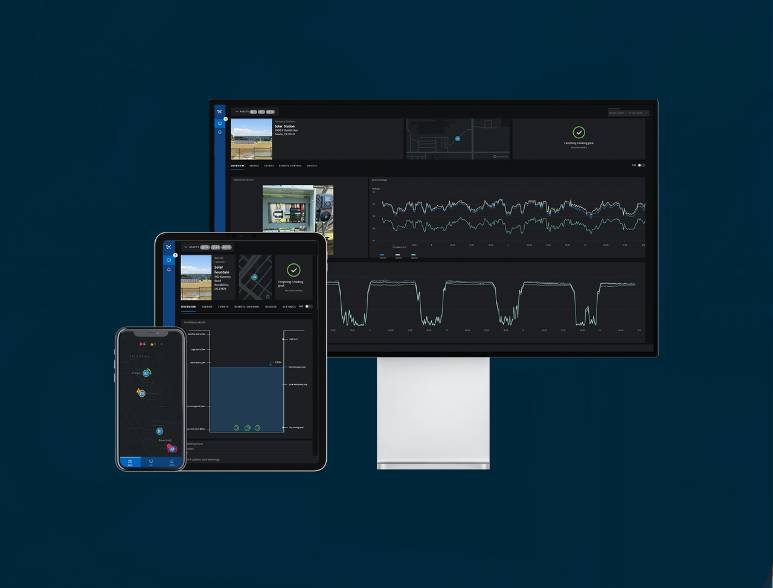

Pump cloud monitoring refers to the continuous collection, transmission, and analysis of pump performance data through an internet-connected platform such as Grundfos Connect Asset Monitor.

How Continuous Monitoring Works at a High Level

- Sensors and controllers gather performance data, typically pressure, flow, and power draw.

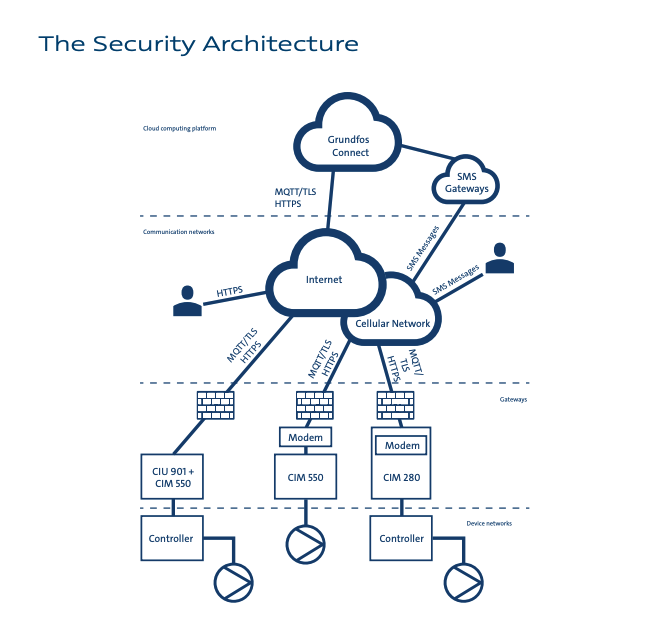

- Gateways send encrypted data from the controller to a secure, cloud-based platform.

- Grundfos maintains the system remotely, reducing the need for on-site programming or service visits.

- Owners can adjust equipment settings and update set-up through the platform portal, as needed.

- Systems scale easily, from single pump stations to multi-site utility networks.

Which Pumps Can Connect?

- Smart pumps (full feature set enabled)

- Legacy pumps with added sensors

- Mixed-OEM pump fleets, with varying levels of functionality

Key Functions of Cloud Monitoring

- Real-time dashboards and performance trends

- Alarm notifications and threshold-based alerts

- Early indicators of performance drift

- Visibility into power trends that may indicate inefficiency

- Remote troubleshooting support to help diagnose issues and recommend next steps

- Long-term data storage for historical comparison

- Remote support from Chamco and Grundfos for emergencies and day-to-day questions

- For Grundfos Machine Health: scheduled check-ins with a Vibration Analyst for ongoing condition monitoring

How Cloud Monitoring Differs From SCADA

While SCADA (Supervisory Control and Data Acquisition) remains essential for whole-facility visibility and customizable automation, cloud monitoring provides:

- Pump-specific visibility and trend information

- Cross-site comparison and portfolio-level visibility

- Long-term cloud storage for lifecycle planning

SCADA is broad and customizable, whereas cloud monitoring, specifically Grundfos Connect, is targeted and specific.

Practical Use Cases for Continuous Pump Monitoring

- Continuously tracking power, pressure, and flow to identify early warning signs or efficiency loss before issues escalate.

- Accessing equipment information and manuals from anywhere to support troubleshooting, training, and faster decision-making.

- Reviewing alarms and performance data off-site to troubleshoot faster and confirm whether an on-site visit is needed (especially valuable for organizations managing multiple stations).

- Assessing trend changes to schedule work proactively rather than reacting to failures after they occur.

- Centralizing oversight to reduce operational strain, supporting fewer unnecessary trips, fewer after-hours call-outs, and faster resolution.

- Maintaining digital logs and performance records to support internal documentation and regulatory reporting requirements (especially for water utilities).

Why Choose Grundfos Connect Asset Monitor?

Generic monitoring tools are designed to serve many systems at once. Asset Monitor is different; it’s built specifically for pumping systems, with functionality that aligns to how pumps actually operate in the field.

Robust Cybersecurity Protections

Cybersecurity is often the first concern operators raise when evaluating cloud-connected pump monitoring.

Grundfos is ISO 27001 certified, the leading global standard for managing and protecting operational data, and adheres to all information security best practices. Combined with multi-layer password protection at the controller level, these measures give operators confidence that system access and pump control remain securely managed.

Designed Specifically for Pumping Systems

Asset Monitor stands out from generic industrial monitoring tools because it is specifically designed for pumping systems, rather than broad automation applications.

Built-in optimization algorithms for Grundfos pumps offer richer performance insights than generic monitoring tools, providing operators with deeper diagnostics and more informed control decisions.

Enables Monitoring of Mixed-OEM Pump Fleets

Many facilities today rely on a blend of Grundfos, legacy, and engineered pump systems. Continuous monitoring must unify these assets.

With Asset Monitor, smart Grundfos pumps often become the “digital anchor” of the fleet, delivering the richest data, built-in optimization algorithms, and the most reliable remote control features.

Legacy or non-Grundfos pumps can still connect through controllers and sensors, providing operators with essential information such as power, pressure, and flow trends. However, these pumps do not access the full optimization algorithms built into Grundfos equipment, so functionality is more limited, and adjustments may remain manual.

Even with reduced capability, connecting non-Grundfos assets still centralizes monitoring and helps operators detect performance changes earlier.

Is Grundfos Connect Asset Monitor Worth It?

Asset Monitor delivers meaningful returns, especially when treated as a long-term reliability strategy rather than a one-off technology purchase.

By providing operators with real-time visibility into pump performance, Asset Monitor enhances uptime, minimizes emergency call-outs, and streamlines troubleshooting across mixed OEM fleets.

Asset Monitor also helps maintenance teams stretch their capacity further by automating reporting and surfacing issues before they escalate.

How a Municipality Saved $30K Per Year With Grundfos Connect Asset Monitor

One of the strongest demonstrations of this technology’s value comes from Chamco’s recent work in Calgary, where a customer experienced four pump failures in just 18 months while operating with a standard controller. After Chamco installed a Grundfos controller connected to Asset Monitor, the station eliminated a $30,000-per-year subcontractor fee tied to manual reporting.

With the controller costing roughly $10,000, the municipality achieved full ROI in under four months, ultimately cancelling a planned purchase from a competing OEM after seeing performance improvements. Results like these highlight the tangible impact of continuous monitoring and remote visibility.

When evaluating costs, organizations should consider gateway hardware, installation and integration, subscription or licensing fees, and the operational savings that arise from reduced maintenance, avoided downtime, and fewer call-outs.

For many facilities, especially those with remote sites or limited on-site staffing, these savings accumulate quickly.

The Future of Pump Monitoring: What Operators Should Expect in the Next 5–10 Years

Pump monitoring is evolving quickly, with connected systems unlocking greater capabilities over the next decade. Artificial Intelligence will play a growing role, augmenting, not replacing, technicians as facilities face rising demands and ongoing staffing constraints.

Connected monitoring enables teams to operate more efficiently and proactively by providing clearer trends, earlier intervention, and better decision support, all without adding headcount. Grundfos is a leader in invention and innovation, backed by a long-standing commitment to research and development. As of today, Grundfos is investing 5.6% of revenue in R&D.

With Asset Monitor, operators can select the features and add-ons that best fit their systems, scaling functionality over time as needs evolve. Facilities that establish these foundations early are better positioned to benefit from richer diagnostics and long-term operational efficiency.

Experience the Benefits of Continuous Monitoring with Grundfos Connect Asset Monitor

Connected pump systems, supported by Chamco and powered by Grundfos technology, form the backbone of smarter, more resilient facilities, as they deliver the meaningful insights operators need to make informed decisions.

Continuous monitoring provides teams with clearer visibility into uptime and equipment health, enabling them to allocate maintenance where it has the most significant impact, rather than reacting to unexpected failures. When pumps operate within an intelligent, coordinated network, organizations gain a level of operational control that compounds in value over time.

Many customers are unaware of the capabilities already available to them through Chamco’s solutions and modern Grundfos controls. Chamco regularly hosts lunch-and-learns and technical sessions to help teams understand what’s possible and make more informed decisions.

Ready to explore whether continuous monitoring and Grundfos Connect Asset Monitor are right for your operation? Chamco’s team can assess your system and recommend the best course of action. Contact us today to get started.

Recent News