CASE STUDY

How Chamco Helped a North American Energy Producer Protect Their Refinery Expansions

Project Background

Due to the expansion of their refinery, the need to replace their portable foam equipment at the Northern Edmonton refinery, and their goal to add the addition of new tanks, a North American energy producer needed an upgrade to their existing fire foam package. This upgrade was essential to be compliant with the fire code protection requirements.

As the bid winner, Chamco was awarded the replacement of three fire foam packages.

The Challenge: Design, Time, and Regulatory Requirements

Chamco was responsible for the design and testing of this significant upgrade. This project presented three key challenges: design, time constraints, and regulatory requirements.

Why This North American Energy Producer Chose Chamco

Chamco’s experience, technical capabilities and competitive pricing surpassed the competitors’ offerings by a long shot. We provided confidence to the energy company every step of the way. Our team spent four weeks responding to clarifications including a face to face meeting in Edmonton with the clients full team addressing any questions or concerns. Chamco never failed to provide our client with a solution to their problems. Chamco’s confidence in our capabilities and ability to address each of the energy company’s pain points left no room for doubt in our capacity to deliver an effective solution.

The Solution

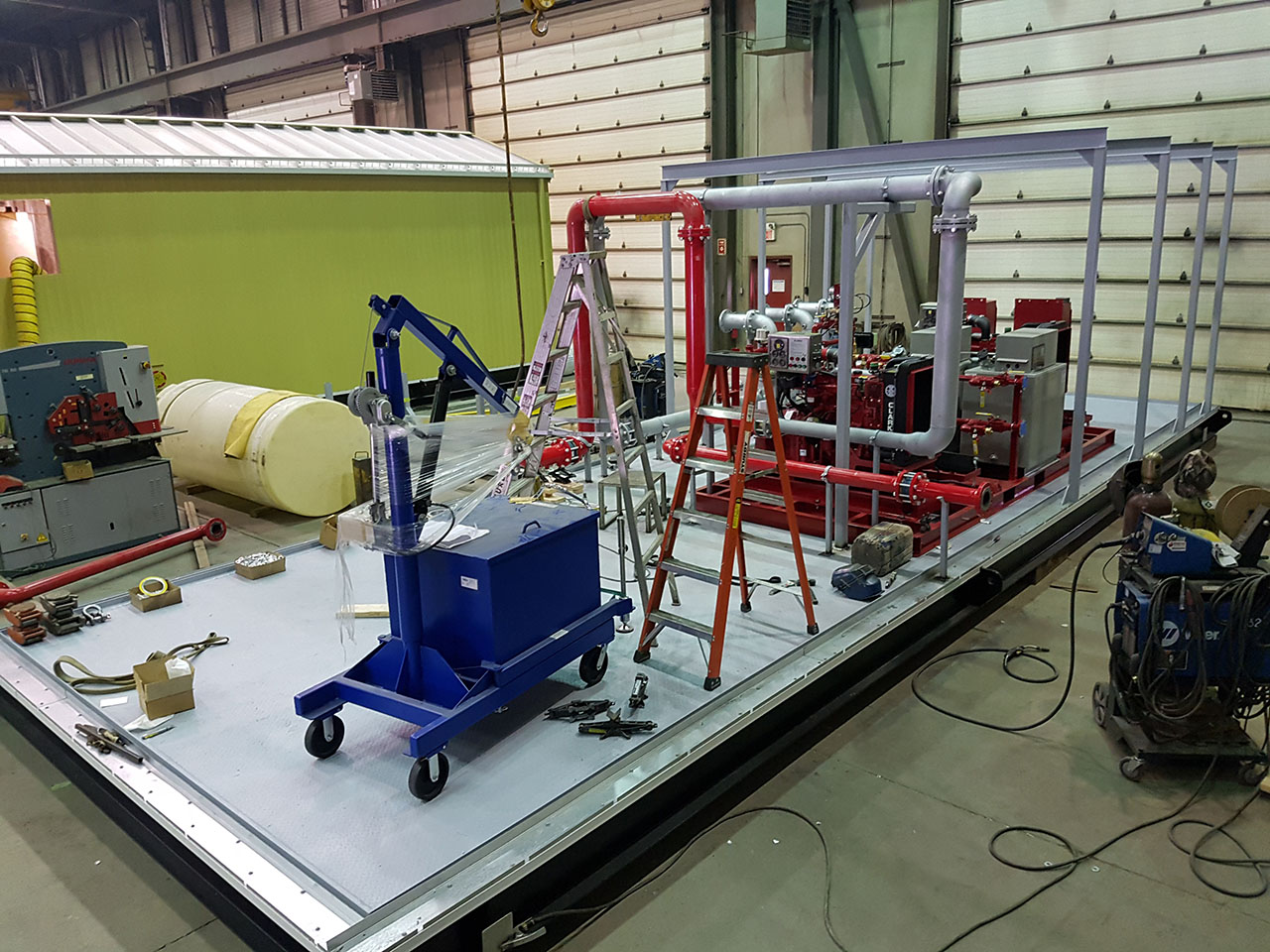

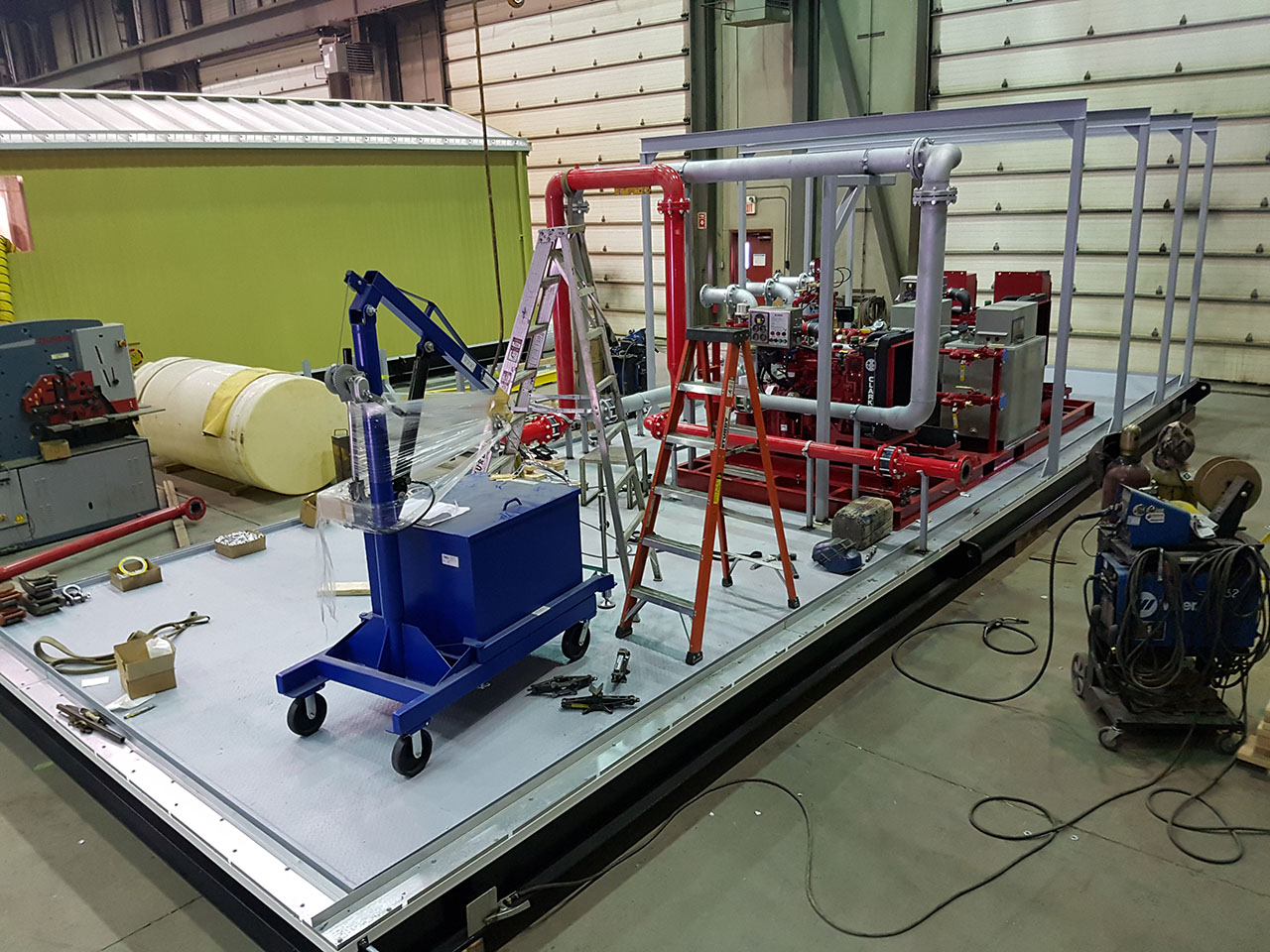

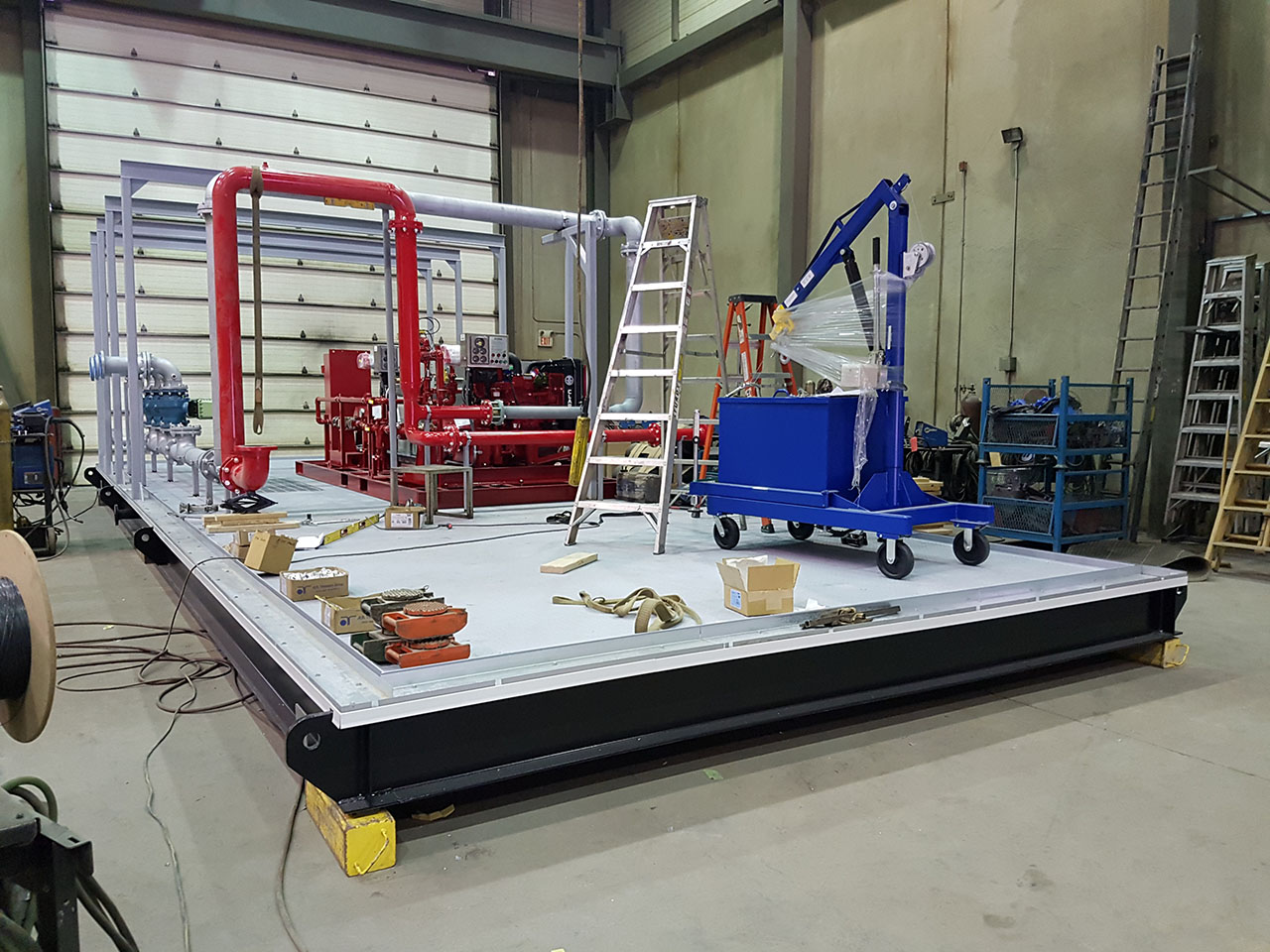

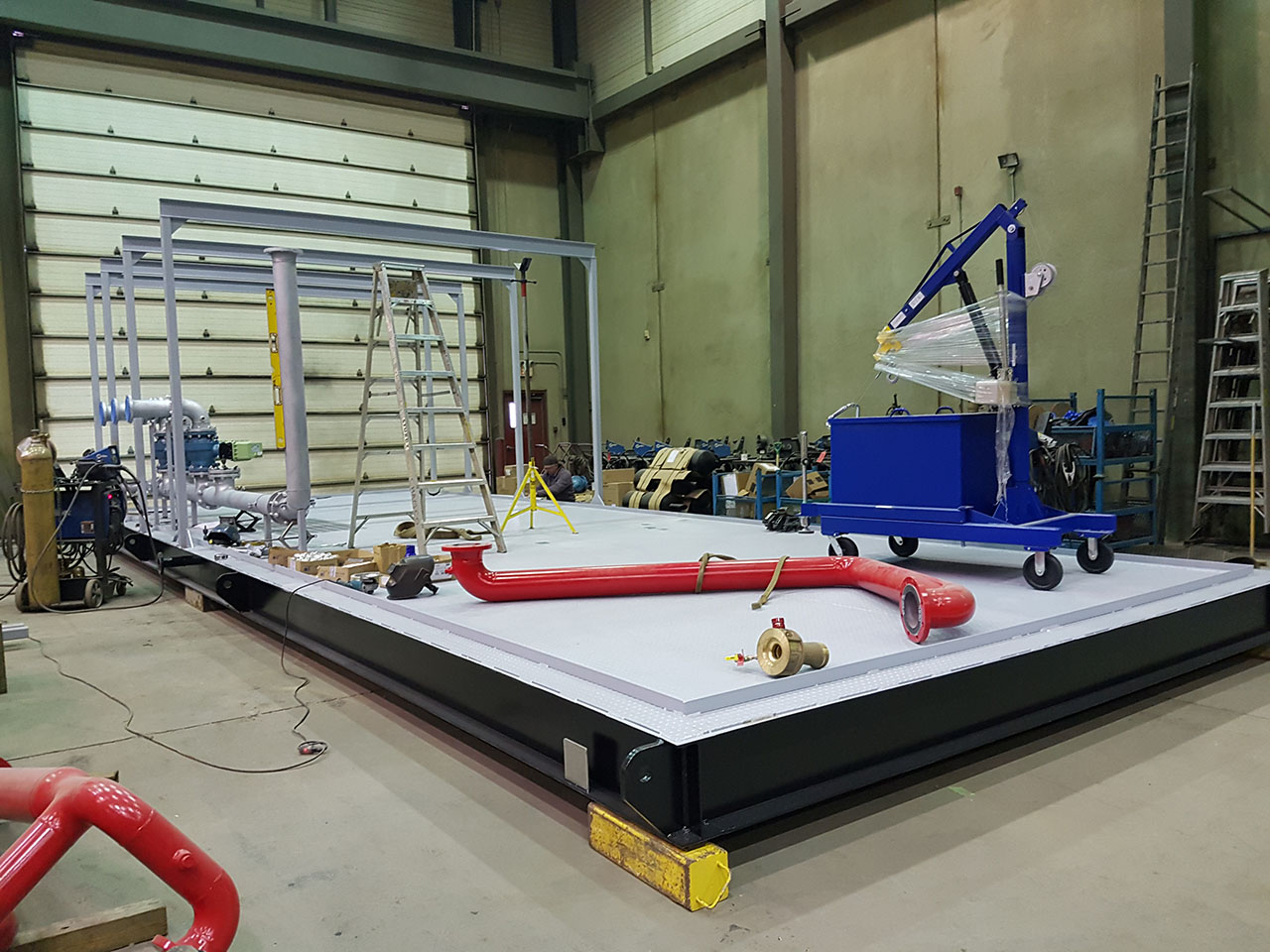

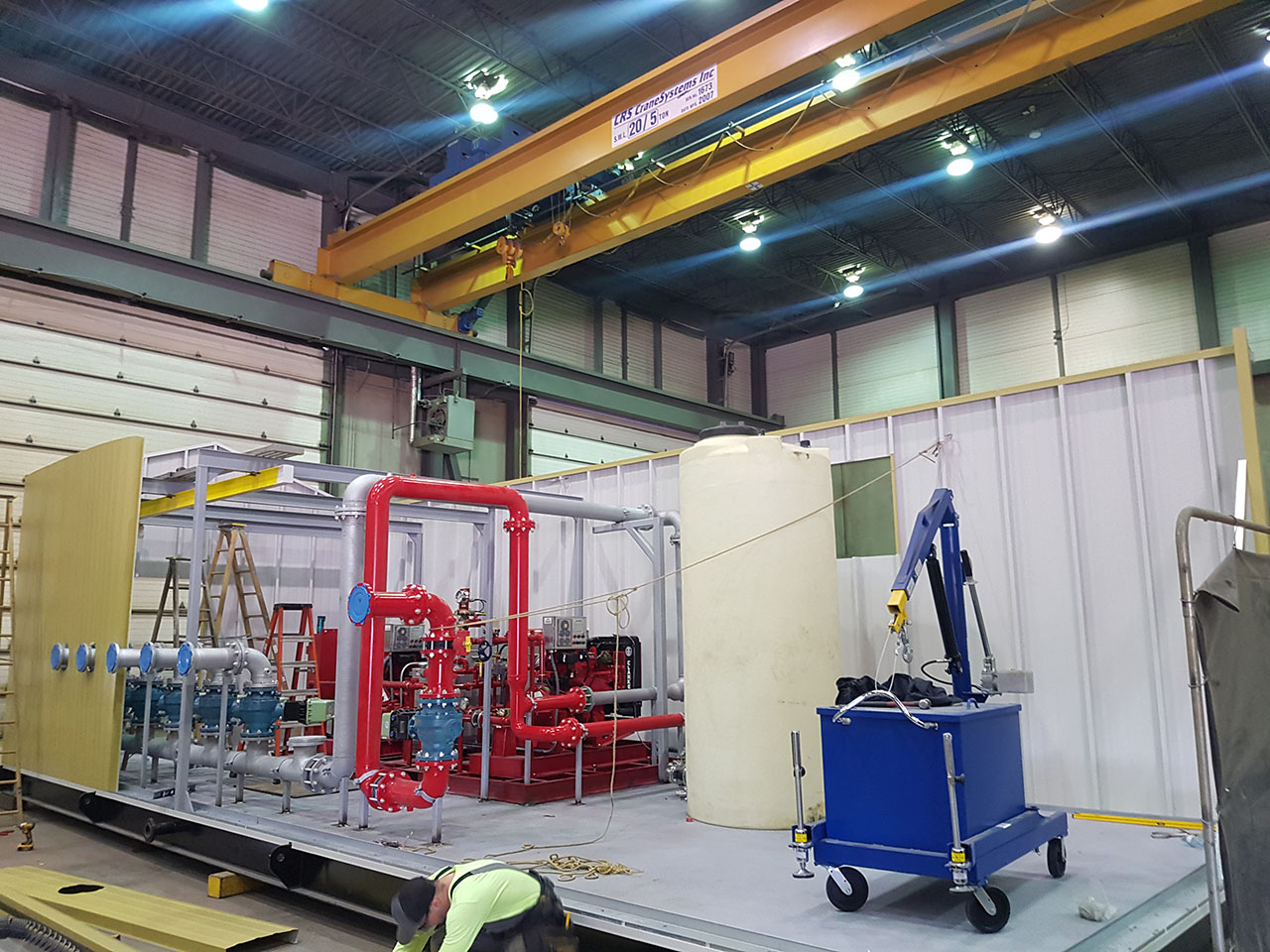

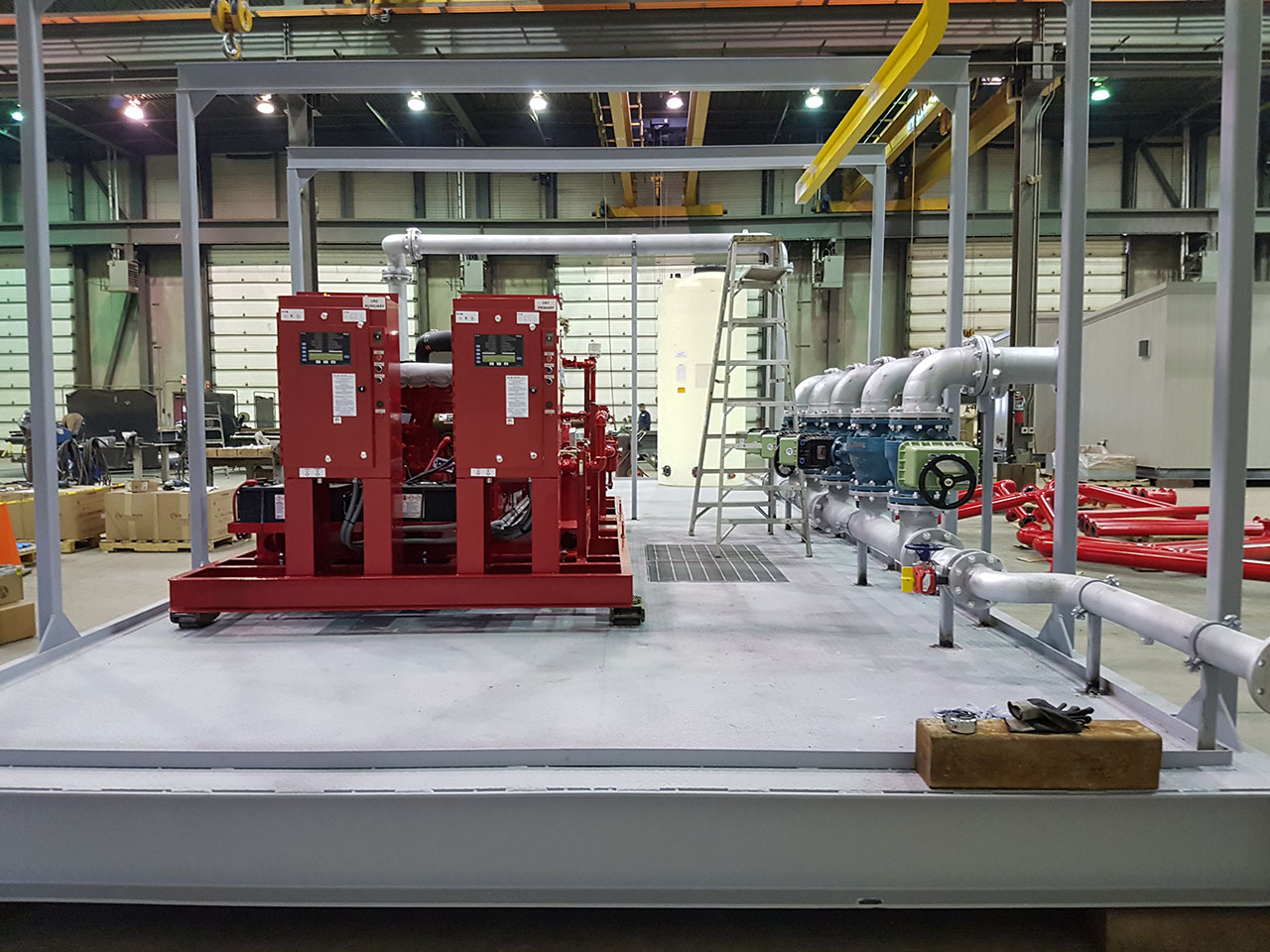

The replacement of three major fire foam packages presented many engineering, logistical, environmental and site-specific challenges. Chamco successfully overcame them and proudly delivered a unique installation to meet our client’s requirements with a fully customized turnkey package. Each package consisted of one foam system, complete with two diesel-driven foam pumps, two diesel-driven engines, concentrate storage tank ratio controller, and fuel tanks as well as the full electrical equipment to allow for a seamless integration to the site’s existing controls system.

The Results

All three fire foam package upgrades were successfully completed and delivered. Chamco’s team ensured the package integrated seamlessly into the refinery’s existing structure, and the final product was tested multiple times with the client’s safety team to provide safe and reliable operation for many years to come

This North American energy producer will continue to benefit from continuous support from Chamco.

“At Chamco, we don’t provide products. We provide solutions.”

Learn more about how Chamco can help with your project.