CASE STUDY

How Chamco Helped Protect Western Canada’s First Diluent Recovery Unit

Project Background

A joint venture between a crude oil infrastructure company and an infrastructure development company was announced in 2019 to construct Western Canada’s first diluent recovery unit (DRU).

As part of the project, Chamco was awarded the fire protection package.

The Challenge: Time, Safety, and Regulatory Requirements

Chamco was responsible for a fully self-contained fire pump package to support the DRU unit, including design, testing, and on-site commissioning. The DRU project presented 3 key challenges: time constraints, safety, and regulatory requirements.

Why The Crude Oil Infrastructure Company Chose Chamco

Chamco was the preferred fire pump supplier for this project due to unsurpassable technical capabilities and years of industry expertise. Being one of the few pump suppliers in Western Canada capable of engineering and designing vertical turbine fire pump solutions, Chamco easily eliminated the competition. Additionally, Chamco’s previous work on an air compressor package for this client allowed us to build a good rapport with the client, leaving no room for doubt on our dependability.

The Solution

Chamco successfully overcame each of the challenges associated with this fire pump project and proudly delivered a unique installation to meet the client’s needs.

The Results

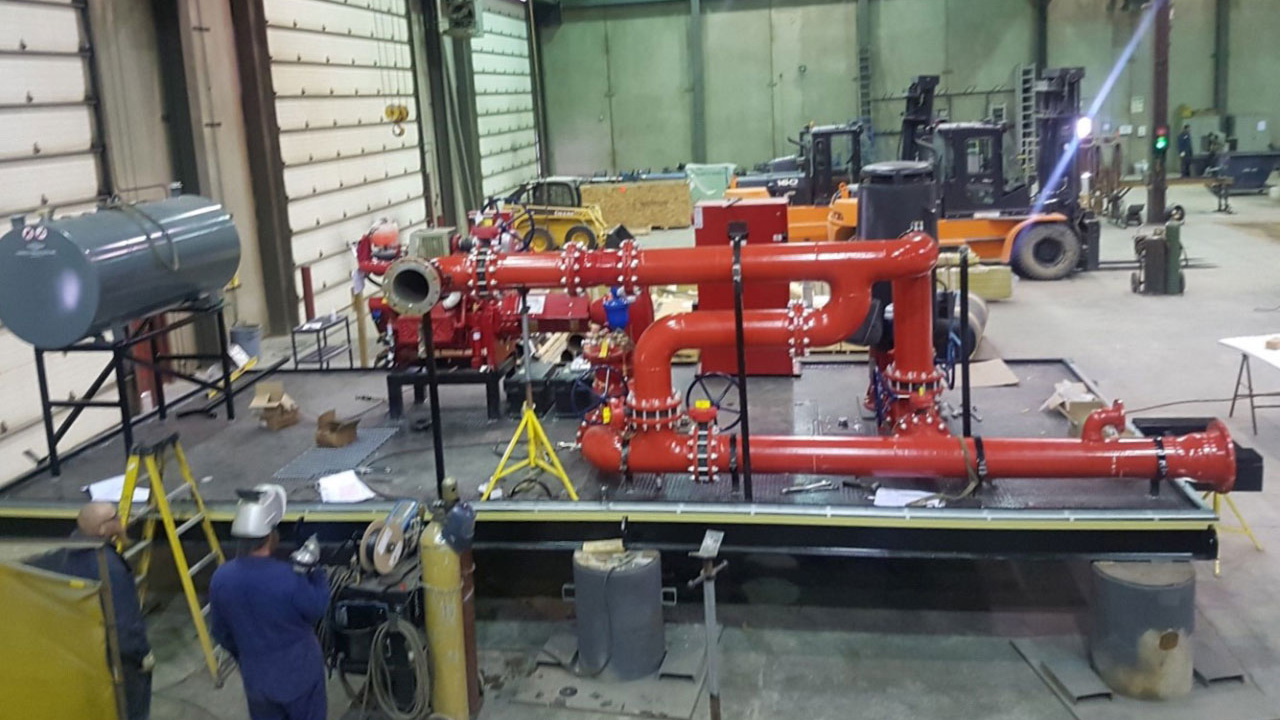

The package consists of one 350HP diesel-driven 2,500 USgmp fire pump, one 300HP electric-driven 2,500 USgmp fire pump, and one 5HP electric-driven 27.6 US GPM jockey pump.

The entire unit is mounted on a long structural steel skid and includes checker-plate decking, spray foam insulation, and a drain sump enclosed in a pre-engineered self-framing building c/w lights, heat and ventilation in accordance with NFPA 20 requirements and designed as a turn-key solution to minimize work required on site.

The unit was successfully built and delivered within the promised 6-month timeline with complete on-site testing and commissioning, providing reliable fire protection to the DRU for years to come!

Learn more about how Chamco can help with your project.